|

| Products » |

|

| SMPS Transformers » |

|

| Toroidal Transformers » |

|

| Ready-to-install Units » |

|

| Air Coils » |

|

| Chokes » |

|

| Audio Transformers » |

|

| Special Projects & Box- Builds » |

|

| LINTRON Part number » |

|

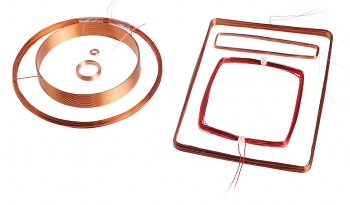

Air Coils

Description

Air coils - also known as coreless coils - are wound without bobbins or magnetic cores, making them highly versatile for a wide range of applications. Their design offers several key benefits:

- High Linearity: With no magnetic core, inductance remains stable across a wide current range, ensuring precise and predictable performance.

- Low Losses at High Frequencies: Air coils exhibit minimal core losses, making them ideal for RF circuits, wireless communication, and high-frequency filtering.

- Excellent Thermal Stability: The absence of a core eliminates magnetic saturation and reduces thermal drift, maintaining reliable performance under varying operating conditions.

- Customizable Designs: Geometry, wire type, and winding style can be optimized for specific inductance values, Q-factor requirements, and space constraints.

- Low Electromagnetic Interference (EMI): Air coils generate lower distortion compared to iron-core or ferrite-based inductors, making them suitable for sensitive electronic circuits.

Custom Coil Design & Manufacturing

At LINTRON, all coils are designed and manufactured according to customer specifications, ensuring precise alignment with electrical, mechanical, and thermal requirements. We offer a wide range of coil types, sizes, and dimensions to meet diverse application needs.

- Flexible Geometries: Available in round, rectangular, and custom shapes.

- Tailored Solutions: Optimized for inductance, Q-factor, current handling, and frequency response.

- Versatile Applications: Suitable for use in filters, resonant circuits, antennas, and power electronics.

Lintron Electronics Ltd, Unit 6b, Wansbeck Bus Pk, Ashington, NE63 8QW, England | Tel: +44 (0) 1670 811888 |

© 1996-2025 Lintron Electronics Ltd. All Rights Reserved. LINTRON is a Trade Mark.